MAGNETIC COUPLING

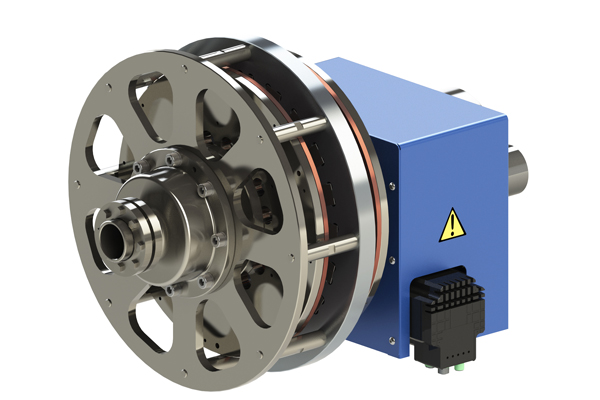

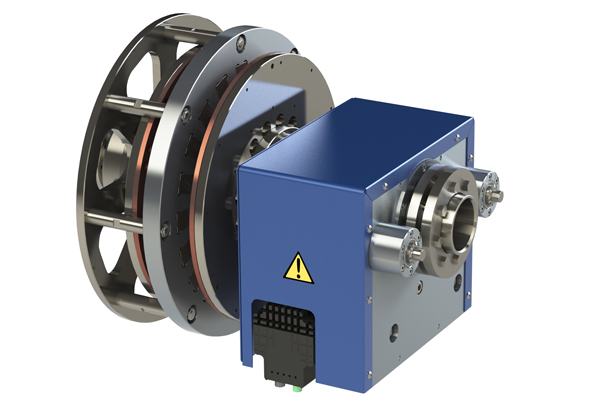

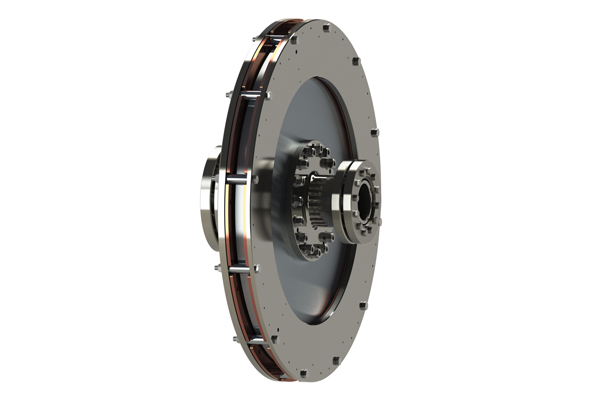

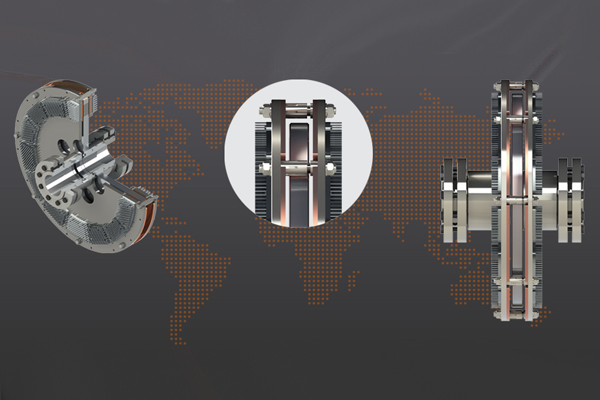

ZYTEC Induction Couplings are connecting each other shaft by maintaining an Air gap. It ensures the separation of the drive and the driven side and the main function is transmitting the power/torque with help of Magnetic Induction. The Conductor Rotor (Copper) is fixed with the Drive Side and the Magnetic Rotor (Permanent Magnets) is fixed in the Driven Side without any physical contacts.

Our Induction couplings are first-class quality with robust design can work reliably& safely even under extreme conditions and available worldwide.

Principle& Operation:

This is an Asynchronous induction coupling; Relative motion between the magnets and the copper creates a magnetic field that transmits torque from motor side to load side. The base frequency of the coupling is the RPM of Motor.

Starting Torque is Zero. Torque is then generated as slip starts to occur which yields a cushioned mechanical start.As the motor accelerates, the magnetic field starts to rotate in the coupling which starts the induction process and torque is produced.

Types of ZYTEC Couplings:

1. F-TORQ – For Fixed Torque

The F-TORQ product replaces standard Fluid Couplings as well a variety of rigid and flexible couplings for both Variable and Constant Torque applications.

2. A-TORQ – For Adjustable Torque

The A-TORQ is specifically designed for variable torque loads (centrifugal fans and pumps) for process control and significant energy savings.

Salient Features:

• Elimination of Laser Alignment

• Greater Misalignment Tolerance

• Minimized Vibration – Increased Seal & Bearing life

• Compact Design

• Cushioned Start

• Increased Reliability

• Overload Torque Protection

• Longer Lifespan

• Greater Functionality

• Lower Maintenance Expense

• Environmental Friendliness

• Lower Down Time

• Can be installed in dirty/outdoor environments

• Energy Saving

Applications:

• Pump – Centrifugal

• Fan – Centrifugal

• Fan – Centrifugal

• Air Preheater

• Agitator/Mixer/Blender

• Bucket elevator/wheels

• Crusher/Grinder/Shredder

• Conveyor

• Generator

• Positive Displacement Pump

• Centrifuge

• Mills – ball/rod/hammer

Industries:

• Maritime

• Mining & Cement

• Water & Wastewater

• Paper & Pulp

• Petrochemical

• Oil & Gas storage

• Food Processing

• HVAC

ZYTEC:

• New State-of-the-Art R&D Center

• Coupling features are regularly tested

• Extensive quality assurance

• Quality Inspections& Assurances

More than 80% of all rotary equipment failures are related to vibration. Vibration breaks down the resiliency of seals and increases bearing and equipment temperatures. Studies indicate that 50% to 60% of damaging machine vibrations are the result of shaft misalignment, 30% to 40% of damaging vibrations are the result of equipment unbalance, and up to 20% are the result of resonance.